We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

FEATURES: Model-Z1T-50A

1. Pipe threading machine is a high integration power pipe tools, This threading machine is the perfect machine for pipeline construction, workshop product,

service trucks and in-house maintenance, or any application where portability and versatility are needed.

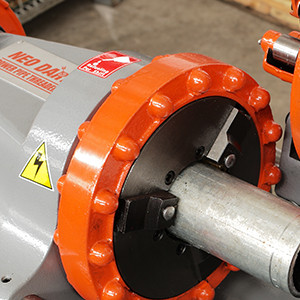

2. The quick-opening die-head threading pipes steady and smooth, from 1/2" to 2".

3. Automatic oiling system produce reliable high quality threads. Self-Priming constant flow gerotor with through the die head oiling.

4. 1.2HP Copper induction motor helps high-perfomance processing, minimize noise,extended service life.

5. Remove burrs by the 5 blade conical reamer.

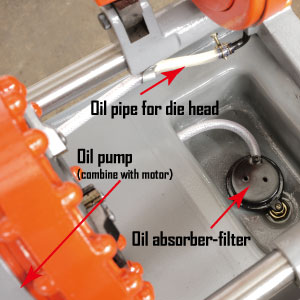

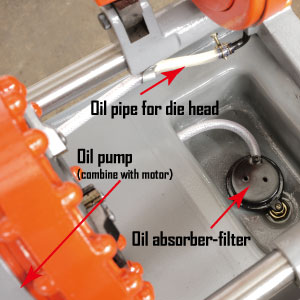

Automatic Oiling System

The automatic oiling system provide high-quality threading and durable using life. The oil pump combine with motor, do not need extra power. There is a filter in the oil tank which to prevent the threaded metal chips mix in to oil circuit.

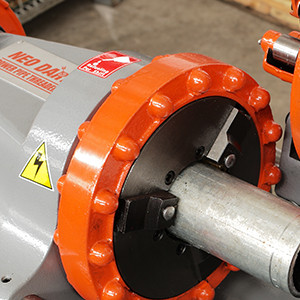

Ergonomics Hammer Chuck

Easy to threading

Processing 1/2"-2" Various Material Pipes

| Model NO. | DSTS-50A |

| Threading Capacity | 1/2" to 2" |

| Horse Power | 1.2 HP |

| No Load RPM | 28RPM |

| Maximum Chuck Capacity | 2" |

| No. of Speeds | 1 |

| Die Head | 1/2" to 2" quick-opening and self-oiling die head. |

| NPT Dies | 1/2" - 3/4" and 1" - 2" Right NPT Fits RIDGID® Dies. |

| Pump | Constant Flow Gerotor. |

| Reamers with Shaft | 5 Blades Conical Reamer. |

| Chuck Type | Hammer chuck with replaceable rocker-action jaw inserts. |

| Foot Switch | NO |

| Voltage Frequency | 110V / 60Hz |

| Amps | 10A |

| Net Weight | 127.9 lbs. |

| Shipping Weight | 154.4 lbs. |

| Packing Size | 27-9/16" × 18-7/8" × 23-1/4" |